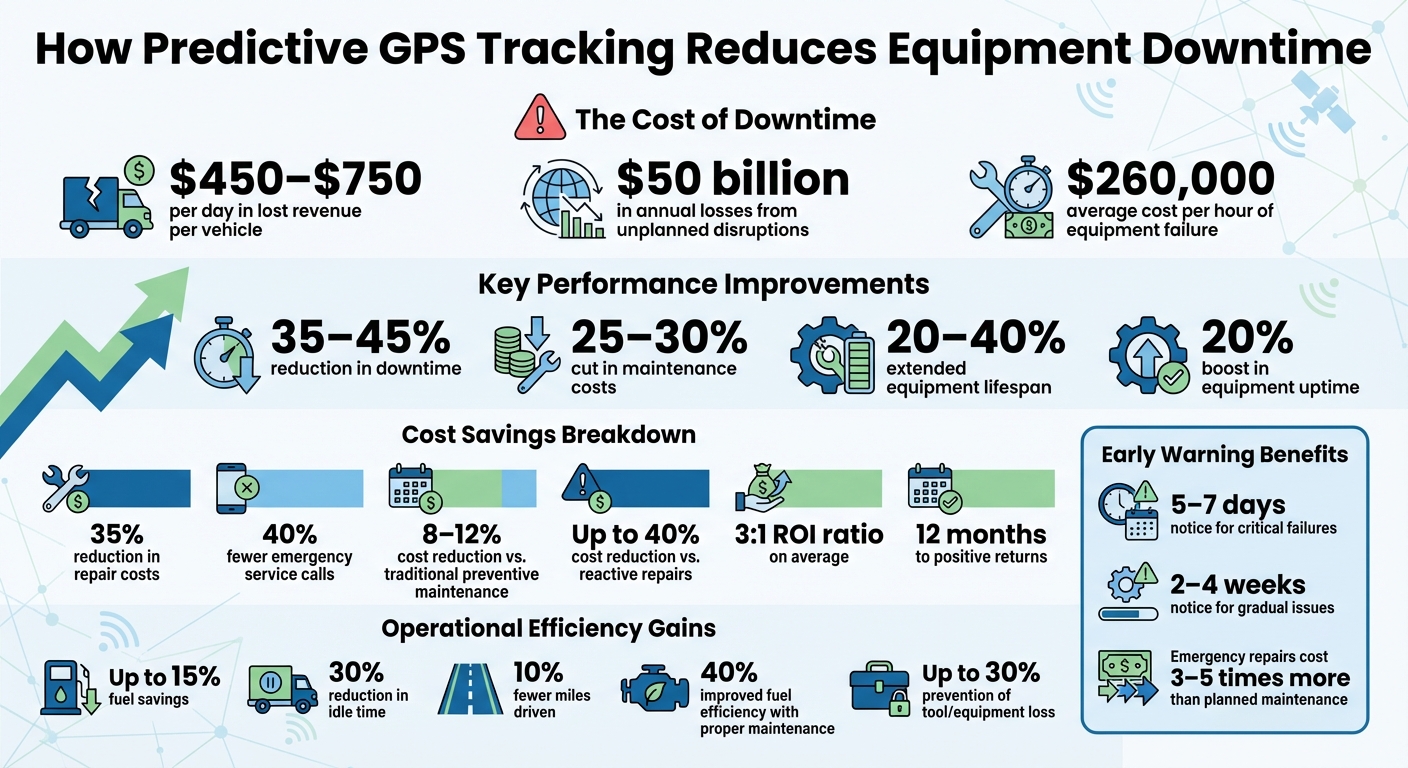

Every day of downtime costs businesses $450–$750, and unplanned disruptions can total $50 billion annually. Predictive systems monitor metrics like engine temperature, oil quality, and vibrations, sending alerts when potential problems arise. This approach slashes downtime by 35–45%, cuts maintenance costs by 25–30%, and extends equipment lifespan by 20–40%.

Key Benefits:

- Fewer Breakdowns: Early alerts prevent costly failures.

- Cost Savings: Lower repair costs, improved fuel efficiency, and reduced labor expenses.

- Longer Equipment Life: Timely maintenance keeps machines running efficiently.

Predictive tracking transforms raw data into actionable insights, ensuring repairs are timely and operations stay on track.

Predictive GPS Tracking ROI: Cost Savings and Downtime Reduction Statistics

How predictive maintenance helps fleets save thousands

How Predictive GPS Tracking Works

Predictive GPS tracking operates through two main processes: gathering real-time data from your equipment and analyzing that information to detect potential issues before they escalate into costly breakdowns. The system connects GPS devices to your equipment using standard wiring setups. These devices work continuously to collect engine diagnostics and usage data, frequently capturing location coordinates and transmitting everything via cellular networks to a cloud-based platform.

Real-Time Data Collection

GPS tracking devices, like Piritiz, act as central hubs, monitoring multiple performance metrics at once. They keep tabs on engine hours, idling habits, battery voltage, and fuel levels, while integrated IoT sensors track additional indicators such as engine temperature, vibrations, oil quality, brake wear, and exhaust emissions. This comprehensive monitoring offers a real-time snapshot of your equipment’s overall condition.

But this system goes beyond just tracking location – it’s about understanding actual wear and tear. For instance, instead of following a fixed schedule for oil changes (e.g., every six months), the device uses real-time data like engine hours and operating conditions to determine when service is genuinely needed. One fleet owner shared that they saved around $1,000 per month per truck in fuel costs by using this tracking data to reduce unnecessary idling.

This constant monitoring forms the backbone for predictive analytics.

Predictive Analytics and Alerts

Once collected, the data flows into a cloud platform where AI and machine learning algorithms analyze it. These systems compare real-time sensor readings against historical data and predefined "failure modes" for specific equipment types. Over time, the platform learns what normal performance looks like for each machine and flags unusual patterns that often signal impending problems. If a parameter exceeds its set threshold – like sudden temperature increases, irregular vibrations, or diagnostic trouble codes – the system sends immediate alerts.

These alerts let you address issues during planned maintenance windows instead of scrambling to fix emergency breakdowns. For example, if the system detects unusual fluctuations in battery voltage, it will notify you to replace the battery during regular business hours, avoiding a potential "no-start" situation in the field. The benefits are clear: GPS-based preventive maintenance can cut unscheduled downtime by up to 20%, while proper vehicle maintenance informed by predictive data can boost fuel efficiency by as much as 40%.

Steps to Implement Predictive GPS Tracking

You don’t need to completely revamp your operations to get started with predictive GPS tracking. It’s a step-by-step process that builds toward creating a reliable and efficient monitoring system.

Step 1: Choose the Right GPS Tracking Devices

Start with selecting reliable GPS tracking devices that suit your assets. For heavy equipment, go for hard-wired, rugged trackers that connect directly to the engine’s diagnostic port. These should be IP67-rated to handle tough conditions like dust, moisture, and extreme temperatures. Beyond just location tracking, look for devices that can pull data such as engine hours, fuel usage, idle time, and fault codes straight from the equipment’s onboard computer.

For smaller assets like generators or compressors, battery-powered trackers are a better fit. Some, like those from Piritiz, offer up to five years of battery life, cutting down on maintenance needs. If you’re tracking trailers or containers, consider solar-powered trackers for continuous monitoring without worrying about battery drain. Matching the device type to the asset is key – basic location-only trackers won’t provide the diagnostic data necessary for predictive maintenance.

Once you’ve chosen your devices, the next step is to install and configure them for seamless data collection.

Step 2: Install Sensors and Configure Alerts

After installing the devices, connect them to your equipment’s diagnostic ports using the appropriate cables (e.g., Caterpillar 9-pin or 14-pin connectors). This setup gives you direct access to real-time engine data and fault codes. For monitoring environmental conditions, use Bluetooth-enabled gateways paired with wireless sensors to track metrics like temperature, humidity, or door status.

Next, set performance thresholds to trigger alerts before issues escalate. For instance, configure notifications for critical changes like engine temperature spikes, oil pressure drops, or low battery voltage. Create geofences around job sites to get instant alerts if equipment moves during unauthorized hours. Transitioning from calendar-based schedules to automated, data-driven alerts can save you unnecessary service visits and help catch problems early. For example, ignoring a “Check Engine” light can lead to repair bills averaging $1,700, while delaying an oil change might cost as much as $3,173.

With sensors and alerts in place, you’re ready to use this data to fine-tune your maintenance strategy.

Step 3: Turn Data Into Actionable Maintenance Plans

Focus on your most critical assets – those with high usage or a history of costly repairs. Define specific "failure modes" for each piece of equipment, such as maximum operating temperatures or acceptable vibration levels. Use a centralized dashboard to monitor these parameters continuously, and let the system generate automated work orders when thresholds are breached. This approach transforms raw data into actionable maintenance schedules.

By shifting from reactive to predictive maintenance, you can plan repairs based on real-time equipment conditions. For example, track idle time separately from mileage, as excessive idling leads to wear that mileage logs won’t capture. Use remote troubleshooting to analyze fault codes before sending out technicians, which can save significant time on diagnostics. As Rich Poppoff, Equipment Superintendent at DeSilva Gates Construction, put it:

"Asset Tag allows us to reinforce existing location tracking on our high-value assets and, for the first time, add tracking to smaller assets that we couldn’t track before".

This level of visibility changes the game for maintenance planning, turning unexpected breakdowns into scheduled service appointments.

sbb-itb-4827db2

Benefits of Predictive GPS Tracking for Equipment Downtime

Predictive GPS tracking is changing the game for fleet management by helping businesses cut down on surprise repairs and keep their equipment running longer.

Fewer Unplanned Repairs

Predictive tracking systems are like having a built-in early warning system for your fleet. Sensors constantly monitor key performance metrics, flagging potential issues before they escalate into expensive emergencies. Fixing small problems early can save a fortune – equipment failures can cost organizations an average of $260,000 per hour. With condition-based maintenance, you service equipment only when real-time data shows it’s necessary, avoiding unnecessary shop visits and surprise breakdowns.

Another perk? Remote diagnostics make troubleshooting faster by providing instant access to fault codes and engine data. Fleet operators using predictive alerts have reported up to 35% savings on repair costs. Catching issues early doesn’t just save money – it also helps preserve the long-term value of your equipment.

Longer Equipment Lifespan

When problems are addressed promptly, equipment stays in top shape for longer. Early detection of issues like unusual vibrations, temperature spikes, or abnormal noises can prevent major damage to key components like the engine or chassis. Monitoring driver habits – such as harsh braking or rapid acceleration – also reduces wear and tear. Predictive maintenance can boost equipment uptime by as much as 20% and extend component life by 20–40%.

Ignoring small issues can snowball into bigger problems. For example, a clogged air filter or low tire pressure forces the engine to work harder, leading to reduced fuel efficiency and faster wear. As Omnitracs puts it:

"Replacing worn-out parts before they create bigger problems helps your vehicles perform at their best for years to come." – Omnitracs

Cost Savings and Efficiency Gains

The cost benefits of predictive GPS tracking go beyond just fewer repairs and longer-lasting equipment. Predictive maintenance can reduce costs by 8–12% compared to traditional preventive methods and up to 40% compared to reactive repairs. These savings come from lower emergency labor costs, better parts management, less downtime, and improved fuel efficiency.

Take Trenitalia, for instance. This Italian train operator equipped 1,500 locomotives with sensors over three years, cutting downtime by 5–8% and saving about $100 million annually by reducing their $1.3 billion maintenance budget by 8–10%.

Smaller operations have seen similar results. Dubbo Regional Council implemented GPS telematics and saved $180,000 on fuel and maintenance combined. Real-time tracking also eliminates wasted labor hours, reduces the time spent searching for parts, and prevents up to 30% of tool and equipment purchases from being lost to theft or misplacement. Monitoring idling, harsh driving, and fuel card usage can even help curb fuel fraud, which eats up as much as 19% of a company’s total fleet costs.

Real-World Examples of ROI with Predictive GPS Tracking

Let’s take a closer look at how predictive GPS tracking translates into measurable returns, particularly in maintenance and operational savings.

Calculating Savings with Predictive Maintenance

Fleet operators who use predictive alerts have reported cutting repair costs by 35% and reducing emergency service calls by 40%. The math is simple: proactive repairs are 4–5 times cheaper than reactive fixes.

Here’s how it works: predictive maintenance minimizes unexpected breakdowns, ensuring equipment doesn’t sit idle and disrupt revenue streams. On average, businesses implementing these systems see a 3:1 ROI ratio and start experiencing positive returns within 12 months.

Timing is everything. Predictive systems provide maintenance teams with 5–7 days’ notice for critical failures and 2–4 weeks for issues that develop more gradually. This early warning system allows repairs to be scheduled during planned downtime, avoiding the steep costs – 3–5 times higher – associated with emergency repairs, premium-priced parts, and overtime labor.

How Piritiz Delivers ROI

Piritiz takes real-time data and turns it into actionable insights, helping businesses save money and operate more efficiently. Their tracking devices, which offer 24/7 monitoring, alert users instantly when equipment performance deviates from the norm. These battery-powered units, with a lifespan of up to 5 years, are designed to prevent surprise expenses.

The platform’s mobile app gives fleet managers a live view of their assets, making it easier to pinpoint underutilized equipment that could be costing money. With plans starting at just $7/month per device on a 2-year agreement, the cost quickly pays for itself. Users typically see fuel savings of up to 15%, a 30% reduction in idle time, and 10% fewer miles driven.

These numbers highlight the practical benefits and financial edge that predictive GPS tracking provides. It’s not just about tracking – it’s about transforming data into smarter decisions.

Conclusion

Predictive GPS tracking takes maintenance to the next level by using real-time alerts for engine fault codes, battery health, and vibration levels. Instead of waiting for equipment to break down, you can plan maintenance based on actual performance data. This means tackling issues during scheduled downtime and grouping services together to cut down on costly emergency repairs.

Switching from reactive fixes to proactive planning can make a noticeable difference to your bottom line. When a vehicle is out of service, it can cost anywhere from $450 to $750 per day in lost revenue. By extending the life of your equipment and keeping operations running smoothly, you not only minimize downtime but also boost your return on investment (ROI). This forward-thinking approach doesn’t just protect schedules – it’s the backbone of smarter tracking solutions.

Piritiz makes this process seamless with GPS tracking devices that provide round-the-clock monitoring and instant alerts. Their battery-powered devices can last up to five years, and plans start as low as $7 per month with a two-year agreement. Whether you’re managing a fleet of vehicles, trailers, or heavy equipment, the platform offers the visibility you need to prevent theft, improve utilization, and simplify operations.

FAQs

How does predictive GPS tracking help lower maintenance costs?

Predictive GPS tracking offers a smart way to cut down on maintenance costs by keeping a close eye on critical equipment metrics like engine temperature, battery health, fuel usage, and tire pressure in real time. It doesn’t just stop at monitoring; the system analyzes this data and provides alerts and automated service reminders, helping you tackle potential issues before they escalate into costly emergency repairs or unexpected downtime.

This kind of forward-thinking maintenance not only saves money but also boosts the longevity of your equipment. With round-the-clock tracking and actionable insights, you can schedule maintenance more effectively and ensure your operations stay on track without interruptions.

Which types of equipment benefit the most from predictive GPS tracking?

Predictive GPS tracking plays a crucial role in managing heavy equipment, mobile assets, and vehicles commonly used in industries such as construction, oil and gas, and logistics. This technology applies to a wide range of assets, including machinery, trailers, and both light- and heavy-duty equipment.

With features like real-time location tracking and maintenance alerts, predictive GPS tracking helps companies minimize downtime, deter theft, and streamline operations. For businesses handling high-value assets, it’s an essential tool to ensure efficiency and security.

How can predictive GPS tracking help reduce fuel costs?

Predictive GPS tracking can play a big role in cutting down fuel costs by tackling two key issues: excessive idling and inefficient routing. For instance, idling vehicles can consume roughly 0.8 gallons of fuel per hour. With real-time data, fleet managers can spot unnecessary idling and send alerts to drivers to turn off engines after a specific idle time. This simple step can lead to noticeable fuel savings.

On top of that, predictive analytics leverage historical data and traffic trends to suggest the quickest and most fuel-efficient routes. Many fleets have seen fuel costs drop by 10–15% after using GPS systems to optimize their routes. With Piritiz’s durable, battery-powered GPS devices, operators can access these insights through a mobile app, ensuring vehicles stay efficient and fuel expenses remain under control.