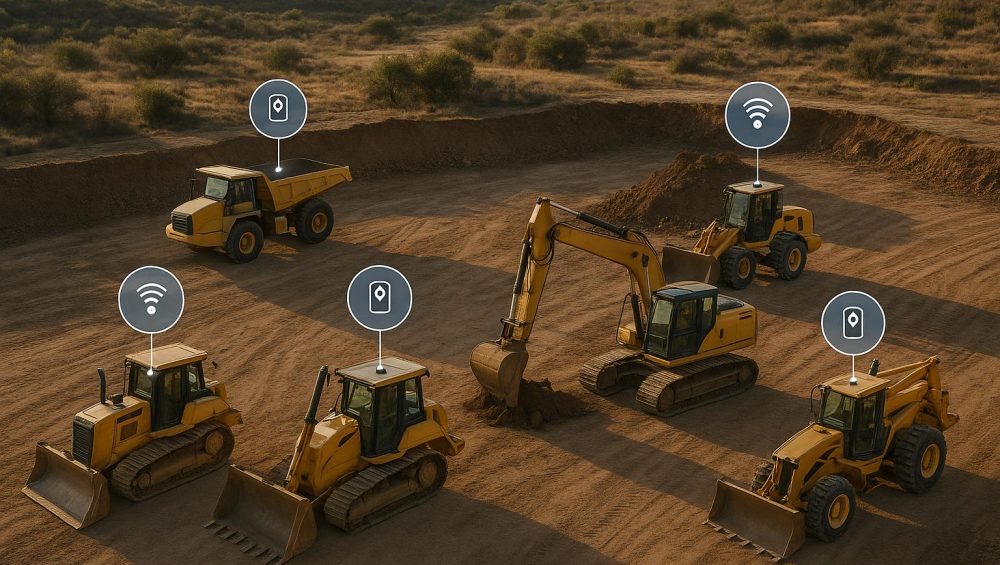

Keeping track of equipment on off-grid job sites can be challenging, especially without access to power. Theft risks, costly delays, and inefficient recovery processes make reliable tracking a must. Fortunately, modern solutions like solar-powered trackers and long-life battery trackers ensure 24/7 monitoring without external power sources. Here’s what you need to know:

- Solar-powered trackers: Use sunlight to recharge, ideal for outdoor equipment in sunny locations.

- Long-life battery trackers: Operate for years on a single charge, perfect for shaded or indoor assets.

- Key features: Durable designs, real-time alerts, and easy installation options like magnetic mounts or adhesives.

- Cost breakdown: Devices range from $100–$330, with monthly service plans starting at $7.

Choose the right tracker based on your equipment type, site conditions, and maintenance preferences. Both options provide dependable asset protection and reduce downtime, ensuring your tools are secure and accounted for.

Power-Free Tracking Options Explained

When you’re working at off-grid job sites, traditional plug-in GPS systems just don’t cut it. And if you’re using basic battery-powered trackers, constant battery changes can quickly turn into a major hassle – especially when equipment sits idle for weeks or months at a time. That’s where power-free tracking solutions come into play.

Solar-powered trackers offer a practical solution by turning sunlight into energy. These devices feature small photovoltaic panels that recharge an internal battery, powering both the GPS module and the cellular transmitter. Even in cloudy or low-light conditions, solar panels often generate enough energy to keep things running. This makes them a great fit for outdoor equipment like excavators, bulldozers, generators, and trailers – basically, anything parked in open areas where sunlight is readily available.

For situations where sunlight isn’t reliable, long-life battery trackers step in as a dependable alternative. These trackers use high-capacity lithium batteries combined with energy-efficient GPS technology. By optimizing power usage, they conserve energy with smart reporting schedules – sending fewer location updates during idle periods and more frequent updates when movement is detected. Some models, like Piritiz trackers, can last up to 5 years on a single charge. They achieve this by staying in a low-power sleep mode until it’s time to collect and transmit location data, cutting down on maintenance needs while ensuring reliable operation.

Each option has its strengths. Solar trackers thrive in outdoor environments with consistent sun exposure, while battery trackers are better suited for equipment in shaded or indoor areas since they don’t rely on light to function.

However, environmental conditions can still impact performance. For example, snow or ice can reduce the effectiveness of solar panels, and extreme temperatures might affect battery efficiency despite modern lithium batteries being designed for tough conditions. Both types of trackers are built to withstand harsh environments, featuring waterproof designs and easy installation options like magnetic mounts or heavy-duty adhesives.

The biggest advantage of power-free trackers? They operate completely independently, with no need for external electrical infrastructure. By transmitting location data over cellular networks, these trackers ensure 24/7 monitoring – no matter where your equipment is located.

How Solar-Powered GPS Trackers Work

Solar-powered GPS trackers harness sunlight to keep themselves running. A solar panel collects sunlight and charges an internal battery through a charge controller. This battery then powers the GPS module and LTE modem, enabling the device to transmit location data seamlessly.

These solar panels are designed to work even on cloudy days. High-quality panels can still generate 25–40% of their typical power output under cloud cover.

The charge controller plays a critical role, sitting between the solar panel and the battery. It regulates the charging process to prevent overcharging or voltage issues, ensuring the system runs smoothly.

The internal battery – usually a lithium-ion or LiFePO4 type – stores the energy collected by the solar panel. This stored energy keeps the tracker operational during periods without sunlight. LiFePO4 batteries are especially dependable, as they perform well in extreme conditions and can last up to four years in standby mode while still sending daily location updates.

When light conditions are poor, trackers switch to a low-power standby mode, reducing the frequency of updates to conserve energy. Even with just a few hours of sunlight per week, these trackers can maintain essential functionality. While cold weather may reduce charging efficiency, LiFePO4 batteries are designed to handle such challenges effectively.

"Sunlight equals uptime, so placement matters." – SpaceHawk GPS

This combination of features ensures continuous tracking, making solar-powered GPS trackers ideal for real-time monitoring and theft prevention, even in areas where power access is limited.

Advantages of Solar-Powered Trackers

One major advantage of solar-powered trackers is their ability to operate almost indefinitely in outdoor environments with regular sunlight. Once installed, they require little to no manual intervention. The automatic recharging process minimizes downtime and eliminates the hassle of frequent battery replacements.

These trackers are particularly useful for equipment parked in open areas. Even in regions with shorter daylight hours during winter, the battery’s stored energy helps maintain functionality during low-light periods.

Their durability is another standout feature. Built to endure tough conditions like dust, rain, and snow, these devices often come with waterproof housings that naturally shed debris. However, occasional cleaning is important, as dirt buildup can reduce solar panel efficiency by up to 20%.

"Cloudy days aren’t the enemy, neglect is." – SpaceHawk GPS

Features to Look For

When selecting a solar-powered GPS tracker, prioritize durability and smart power management.

- Durability: Opt for trackers with waterproof housings that can withstand rain, snow, and dust. They should also be rugged enough to handle vibrations and impacts, especially in demanding environments like job sites.

- Reliable Connectivity: Ensure the tracker supports LTE for consistent data transmission, even in remote areas.

- Battery Capacity: While solar charging is a game-changer, a larger internal battery provides extra backup during extended cloudy periods. For instance, some models come with 10 Ah rechargeable lithium batteries capable of delivering up to 4,000 GPS positions on a single charge.

- Efficiency: Look for monocrystalline solar panels, which are known for their 18–22% efficiency. These panels charge faster and perform better in low-light conditions. Advanced power management features, such as intelligent battery algorithms, optimize energy use by adjusting GPS update rates based on battery levels.

- Mounting Options: Proper placement is key. Choose a clean, flat surface with maximum exposure to sunlight to ensure optimal performance.

Long-Life Battery Trackers: Power Without Solar

Long-life battery trackers rely on built-in batteries designed to last for extended periods – ranging from weeks to years – without requiring solar charging. These devices are built for energy efficiency, making them ideal for stationary equipment or assets in locations where solar power isn’t practical.

Their impressive battery life comes from adjustable tracking intervals. By transmitting updates at set intervals – hourly, daily, or even weekly – they conserve energy while still delivering essential location data. Depending on the settings, some models can last over 10 years with minimal updates. This makes them a great choice for equipment in areas where solar charging isn’t feasible, emphasizing the importance of customizable reporting schedules.

These trackers use lithium batteries, which perform reliably even under extreme temperatures. While they sacrifice constant, real-time updates, they offer extended operational lifespans. If immediate location updates are critical, a continuously powered tracker might be a better fit. However, for assets that rarely move, periodic updates – once or twice a day – are often sufficient.

To enhance security, these trackers include alert systems that notify users of unexpected movements, boundary crossings, or tampering. These alerts are designed to activate quickly, providing theft protection without draining the battery excessively.

Durability is another key feature. Designed for challenging environments, these trackers often come in rugged, weather-resistant enclosures to withstand rain, dust, vibration, and impacts. This ensures they remain dependable even in harsh conditions.

When to Use Long-Life Battery Trackers

Long-life battery trackers are perfect for scenarios where assets remain stationary or move infrequently.

For instance, trailers parked at customer sites for weeks or months only need occasional location updates to confirm they’re still in place. Similarly, dumpsters and waste containers, often in shaded or covered areas where solar charging isn’t effective, benefit from these low-maintenance devices. Stationary machinery like generators, compressors, or welding equipment, as well as equipment stored indoors or in covered spaces, can also be effectively monitored with these trackers.

If your equipment rarely moves, these trackers provide a hassle-free solution with years of operation between battery replacements. However, for assets requiring continuous, real-time tracking, a powered alternative might be a better fit.

How to Extend Battery Life

You can maximize the lifespan of long-life battery trackers by making a few adjustments.

- Adjust reporting frequency: Switching from real-time updates to hourly or daily check-ins can extend battery life significantly – by up to 10 times. Many tracking platforms allow you to customize these intervals, so you can increase updates during high-risk periods and scale back during routine operations.

- Regular maintenance: Although these trackers require minimal upkeep, occasionally checking for secure mounting, intact housing, and cleanliness helps maintain efficiency.

- Avoid temperature extremes: Mount trackers in locations that minimize exposure to direct sunlight or extreme cold, such as inside equipment compartments.

- Optimize alert settings: Configure geofences and movement thresholds carefully to avoid unnecessary notifications, which can drain the battery.

- Refine connectivity settings: If your equipment operates in open areas with strong GPS signals, you can deactivate advanced features like Wi-Fi sniffing or multi-GNSS systems to save power.

Finally, choose a tracker that matches your specific needs. For example, devices like those from Piritiz offer up to 5 years of battery life, making them ideal for long-term use on trailers, equipment, or fleet vehicles. With flexible monthly plans starting at $9.95 and no long-term contracts, they provide a cost-effective way to monitor assets without frequent battery changes.

Installing and Securing Trackers on Equipment

Ensuring trackers are installed securely is essential for uninterrupted monitoring on job sites, especially those without power. A well-installed tracker is less likely to fall off during transport, succumb to harsh weather, or become an easy target for theft. Choosing the right mounting method not only prevents data gaps but also saves you the trouble of replacing lost or damaged devices.

The good news? Most trackers are designed for quick installation – usually in under five minutes. However, taking a little extra time to choose the best method can make all the difference in performance.

Mounting Methods for Different Equipment

Different equipment types require specific mounting solutions based on factors like movement, storage, and exposure to the elements. Here are some common options:

- Magnetic mounts: These are perfect for metal surfaces like trailers, generators, or steel containers. They’re quick to install and don’t require drilling. However, they’re not ideal for equipment that vibrates heavily or for non-metal surfaces like fiberglass or plastic.

- High-strength adhesive tape: Industrial-grade tape works on almost any surface and provides a strong, tool-free bond. It’s durable enough to withstand vibrations, temperature changes, and moisture.

- Bolt-mounted installations: For high-value equipment or areas prone to theft, bolt-mounted trackers are a secure choice. Tamper-resistant bolts or anti-theft screws with custom bits add an extra layer of protection, making it harder for unauthorized removal.

- Internal mounting: Installing trackers inside enclosed compartments – like battery boxes, tool compartments, or under seats – offers natural protection against weather and tampering. Just make sure to avoid areas with metal interference.

- Camouflage techniques: Some trackers can be painted to match the equipment, making them harder to spot and less likely to be tampered with.

- Rugged, waterproof housings: Trackers with IP67 or IP68 ratings are built to withstand rain, dust, and impacts. These are especially useful on construction sites where equipment often faces rough conditions.

Selecting the right mounting method ensures your tracker is secure and ready to perform in any environment.

Tracker Placement for Best Results

Once the tracker is securely mounted, proper placement is key to ensuring it works at its best. Whether it’s about getting a strong GPS signal, optimizing solar charging, or protecting the device, here’s what to keep in mind:

- GPS signal reception: Place trackers where they have a clear view of the sky, away from metal obstructions. Mounting them on the top or upper surfaces of equipment typically provides the best signal. If indoor installation is necessary, choose spots near windows or openings.

- Solar-powered trackers: For solar models, sunlight is crucial. Install them on horizontal surfaces facing upward or on south-facing vertical surfaces (if you’re in the Northern Hemisphere) to maximize sunlight exposure. Avoid shaded areas, as even partial shading can affect charging efficiency.

- Battery-powered trackers: These offer more flexibility since they don’t rely on sunlight. They can be placed in covered areas, compartments, or indoor spaces. However, it’s still wise to avoid spots with extreme temperatures.

- Discreet placement: To deter theft, consider hiding trackers in less obvious spots like under trailer frames, inside toolboxes, beneath seats, or within recessed areas of equipment.

- Vibration considerations: For equipment exposed to frequent movement or rough terrain, avoid mounting trackers in high-vibration areas like engine mounts or suspension components. If unavoidable, use padding or vibration-dampening materials to reduce wear and tear.

After installation, test the tracker to ensure it provides accurate location data and maintains a strong signal. For solar-powered devices, monitor battery levels over a few days to confirm adequate charging. If signal or charging issues persist, adjust the placement as needed.

Lastly, keep a record of each tracker’s mounting location. A simple spreadsheet with equipment IDs, tracker serial numbers, and installation details can make future maintenance easier and help your team quickly locate devices when needed.

Taking the time to install and place trackers properly ensures your system remains reliable and effective.

sbb-itb-4827db2

Real-Time Monitoring and Security Alerts

Once your trackers are installed and up and running, real-time monitoring transforms them into active security systems. These systems can alert you immediately to unauthorized movement, tampering, or boundary breaches, ensuring you’re always in the loop.

For off-grid job sites, this feature is a game-changer. Remote locations are often more vulnerable to theft simply because they’re harder to monitor in person. With instant alerts, you can act quickly – recovering equipment before it’s gone for good or even stopping theft in its tracks. This constant connection strengthens the security measures you’ve already put in place.

Key Alert Features You Should Know

Modern GPS trackers come with a range of alert options designed to spot issues early. By understanding these features, you can tailor your system to address the specific risks at your job site.

- Geofencing: This feature lets you create virtual boundaries around your site or storage areas. If equipment crosses these invisible lines or moves unexpectedly, you’ll receive an immediate notification. This is especially helpful for monitoring equipment overnight or during weekends when no one’s on-site. You can set up multiple geofences, like one for the primary work area and another for designated storage zones.

- Tampering Alerts: These alerts notify you if someone tries to disable or remove the tracker. They can detect when the tracker’s housing is opened, removed, or handled unusually. Some models also send alerts if the device suddenly loses power, which could indicate tampering.

- Vibration Detection: This monitors for unusual vibrations, like someone trying to load equipment onto a truck or operating machinery without permission. It’s smart enough to differentiate between normal environmental factors, like wind or nearby traffic, and actual threats.

- Low Battery Warnings: For battery-powered trackers, these alerts let you know when the charge is running low. This ensures you can recharge or replace the device before it stops working.

Most tracking platforms allow you to customize alert settings to suit your needs. For example, you might want instant notifications for geofence breaches but only daily updates for battery levels. Platforms like Piritiz make this easy to manage through their mobile app, giving you the exact information you need without overwhelming you with unnecessary notifications.

Why Real-Time Monitoring Matters

When paired with proper installation and secure mounting, real-time monitoring ties everything together to keep your equipment safe.

- Quick Response: If your equipment starts moving off-site in the middle of the night, you can immediately alert local authorities. With live location data, law enforcement has a much better chance of recovering stolen equipment before it’s dismantled or transported out of state.

- Fewer False Alarms: Intelligent alert systems can adapt to normal activity patterns. For instance, if your crew regularly moves equipment during work hours, the system can suppress alerts during those times while remaining vigilant overnight. This reduces unnecessary notifications and ensures you focus only on real threats.

- Automatic Recordkeeping: Every movement is logged with timestamps, creating a clear record of when and how equipment was used. This data can be invaluable for resolving disputes, filing insurance claims, or conducting internal reviews.

- Operational Insights: Over time, monitoring can reveal patterns in equipment usage. You might find that certain tools are sitting idle for long periods or that equipment is being moved more often than necessary, leading to wasted fuel and labor. These insights can help you streamline logistics and allocate resources more effectively.

- Peace of Mind: For smaller contractors, the financial hit from stolen equipment can be devastating. Knowing you’ll be alerted the moment something goes wrong lets you focus on running your business without constantly worrying about security. With platforms like Piritiz offering 24/7 tracking access via mobile apps, you can check on your equipment anytime, whether you’re at home, on another job site, or even out of town.

The key to getting the most out of real-time monitoring is customizing your alerts. Strike the right balance – too many notifications can be overwhelming, while too few might leave you unaware of critical events. Fine-tune your settings based on what works best for your operation.

Solar vs. Long-Life Battery Trackers

Now that you know how solar-powered and long-life battery trackers operate, the next step is deciding which one suits your job site’s conditions best. Each type has its own advantages, and the right choice depends on factors like how your equipment is used, the location of your site, and how much maintenance you’re willing to handle. Let’s break down these considerations for both types of trackers.

Solar-powered trackers shine in environments where equipment is outdoors most of the time. If your job site is in a sunny location – think Arizona, Texas, or California – the solar panel continuously powers the tracker by harvesting energy during the day and storing it for nighttime use. This setup minimizes the need for frequent battery replacements, making it a practical choice for sunlit, open areas.

On the flip side, long-life battery trackers are ideal for settings where sunlight is scarce or equipment is often kept under cover. For example, in regions like the Pacific Northwest or during winter months, where sunlight is limited, battery-powered units are a better fit. These trackers can operate for up to five years without needing a battery replacement, depending on your reporting settings. Companies like Piritiz offer GPS trackers designed for long-term, low-maintenance performance in such conditions.

When it comes to maintenance, solar trackers require occasional cleaning, especially in dusty or muddy environments like gravel quarries or desert construction sites. Dirt and debris can reduce the panel’s efficiency. Battery trackers, however, demand very little upkeep until the battery needs replacing, which can be a big plus when managing a large fleet.

Cost is another key factor. Solar trackers typically have a higher upfront price due to the added hardware, such as the solar panel and charging components. However, they save on ongoing costs by eliminating the need for frequent battery replacements. Battery trackers, by contrast, are cheaper to purchase initially but involve occasional replacement costs. Over time, especially with extended battery life models, the overall expenses can balance out.

Weather resilience also plays a role. Both types are built to endure tough conditions, but solar panels – being an exposed component – can be more vulnerable to damage from hail or falling debris. Battery trackers, being more compact, can often be installed in concealed locations, reducing the risk of damage or tampering.

Feature Comparison Table

| Feature | Solar-Powered Trackers | Long-Life Battery Trackers |

|---|---|---|

| Power Source | Solar panel with backup battery | Internal battery (lithium or similar) |

| Continuous Operation | Runs continuously with sunlight | Up to 5 years, depending on settings |

| Upfront Cost | Higher due to additional hardware | Lower with fewer components |

| Ongoing Costs | Minimal (cleaning/maintenance) | Occasional battery replacement |

| Maintenance | Periodic solar panel cleaning | Minimal until battery replacement |

| Best For | Outdoor equipment in sunny areas | Indoor or low-sunlight environments |

| Installation Complexity | Moderate (requires panel orientation) | Simple with flexible placement |

| Weather Vulnerability | More exposed to environmental factors | Compact, with fewer exposed parts |

| Ideal Environments | Open sites, outdoor storage, sunny regions | Warehouses, enclosed yards |

| Reporting Flexibility | Frequent updates without power concerns | Extended battery life for less frequent updates |

The table highlights that neither tracker type is universally better – it all depends on your specific needs. For instance, if you manage a mixed fleet where some equipment is stored outdoors and other pieces are kept indoors, using both types might be the smartest approach. Solar trackers can handle outdoor machinery, while battery-powered units like those from Piritiz provide reliable tracking for indoor equipment.

Security is another consideration. Solar panels are more visible, which could make them a target for tampering. Battery trackers, on the other hand, are more discreet and less likely to attract attention. Some solar trackers do come with tamper alerts to notify you if the device is disturbed, adding an extra layer of security.

Ultimately, the choice comes down to aligning the tracker’s features with your operational needs, site conditions, and how much maintenance you’re prepared to handle. Both options provide dependable tracking for off-grid environments – select the one that fits your workflow best.

Cost Analysis for Long-Term Use

When considering equipment tracking systems, it’s important to look beyond the initial purchase price. These systems often justify their cost over time by reducing maintenance expenses, preventing theft, and improving operational efficiency. This ties directly into the broader advantages of tracking technology, emphasizing its role as a smart investment.

The cost of devices varies depending on the technology used. For example, 4G solar-powered trackers typically range between $100 and $180, while satellite models are priced higher, around $299 to $330. Trackers with long-life batteries generally cost about $160.

Monthly service fees are another factor to consider. For instance, many 4G solar trackers have service fees ranging from $13.95 to $15.00 per month per device. Companies like Piritiz offer more affordable options, with plans starting at $9.95 per month and dropping to $7.00 per device with a two-year prepaid plan. Satellite-based trackers, however, tend to have higher data costs compared to their 4G counterparts.

The real savings come from the system’s ability to lower ongoing costs. Solar-powered trackers minimize or eliminate battery replacement needs, cutting down on labor and maintenance. Long-life battery trackers, on the other hand, can operate for several years before requiring attention. GPS tracking also acts as a theft deterrent and aids in recovering stolen equipment, saving businesses from potentially significant financial losses. Additionally, precise location data streamlines equipment management by reducing search times, optimizing maintenance schedules, and improving asset utilization – all of which enhance crew productivity and operational efficiency.

Long-Term Savings and ROI

While the upfront investment may seem steep, the long-term savings often outweigh the initial costs. Over several years, businesses benefit from reduced service fees, lower maintenance costs, enhanced security, and better asset utilization. Many contractors quickly recover their investment through theft prevention, minimized equipment downtime, and labor optimization.

Thinking of tracking systems as a tool for efficiency and risk management shifts the perspective on their value. Over time, the data collected by these systems helps businesses make smarter decisions about equipment purchases, deployment, and maintenance strategies. This leads to better performance and consistent cost savings, making tracking systems an integral part of effective equipment management.

Choosing the Right Tracker for Your Needs

Finding the right tracker means considering your equipment, how you plan to use it, and how much you’re willing to spend. These factors ensure you get a tracker that fits your needs without unnecessary expenses.

Equipment Type:

If you’re dealing with unpowered equipment, like generators, compressors, or hand tools, long-life battery trackers are a solid choice. These trackers are built for smaller assets and only require occasional updates. Some models even offer a battery life of up to 7 years.

Budget Considerations:

It’s not just about the initial cost – think about the ongoing service fees too. For instance, Piritiz offers plans starting at $7 per month when you commit to a two-year prepay plan. This can make it easier to manage your long-term costs.

Finally, make sure the tracker you choose matches your update frequency needs and can handle the environmental conditions of your job site. This ensures it performs reliably where and when you need it.

FAQs

What’s the best way to choose between solar-powered and battery-powered trackers for job site equipment?

When choosing between solar-powered and battery-powered trackers, it’s important to weigh your job site conditions and equipment requirements.

Solar-powered trackers are ideal for locations with plenty of sunlight. They can save you money over time by cutting down on frequent battery replacements. However, they might struggle to perform effectively in shaded or low-light areas.

On the flip side, battery-powered trackers deliver consistent performance no matter the weather or lighting. They’re particularly useful for equipment used indoors or in covered spaces. The trade-off? You’ll need to account for regular battery replacements.

To decide what works best, think about factors like initial costs, upkeep, and how well each option suits your job site’s environment.

What should I keep in mind when installing and positioning trackers for the best performance?

To get the most out of your trackers, keep these important points in mind:

- Unobstructed View of the Sky: Place your trackers where they have a clear, open view of the sky to maintain a strong GPS connection. Avoid areas like enclosed spaces or under heavy metal structures that could interfere with the signal.

- Secure Attachment: Make sure the tracker is firmly mounted to prevent it from coming loose during use or transport. Opt for sturdy mounting equipment that matches the conditions of your worksite.

- Protection from Harsh Conditions: Keep trackers away from spots with excessive dirt, moisture, or extreme temperatures. If needed, use protective cases to shield them from tough environmental elements.

Taking these steps will help ensure your tracking devices perform reliably and deliver accurate data, even in demanding job site conditions.

How can real-time monitoring and security alerts improve safety and efficiency on job sites without power?

Real-time monitoring and security alerts are essential for maintaining safety and smooth operations on off-grid job sites. They let you track your equipment in real time, even in remote areas, so you can address problems like theft or unauthorized use as soon as they occur.

Many modern tracking devices come equipped with long-lasting batteries or solar-powered options, making them well-suited for locations with limited access to power. These tools deliver reliable performance, helping minimize downtime and giving you greater control over your equipment. By staying updated and prepared, you can bolster site security and keep operations running efficiently, even in tough environments.